- Messages

- 20,228

- Location

- Springfield, Missouri

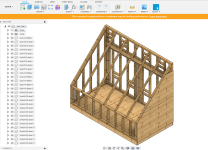

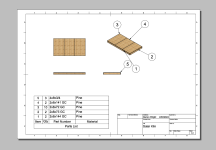

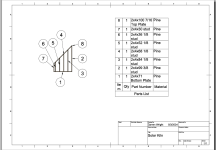

I've been trying to learn F360 and also trying to make sense of the Virginia Tech solar kiln plans, so thought it would be a good opportunity to draw something.

Can view it in the viewer here: https://a360.co/4dsJKkY

Can view it in the viewer here: https://a360.co/4dsJKkY

For those corner columns, are you planning to use stacked 2x4s or will they be single pieces of wider boards?

For those corner columns, are you planning to use stacked 2x4s or will they be single pieces of wider boards?