- Messages

- 11,666

- Location

- Constantine, MI

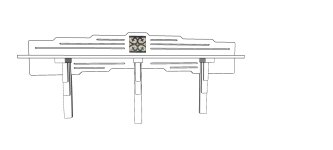

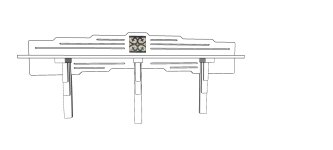

Next project on the schedule is this hanging entryway shelf. I designed this for a client in Oregon who is a fan of G&G. He likes for me to add lots of G&G touches. Lots.

It will be walnut with ebony accents. The back plate takes its deign ques from several ceiling fixtures, primarily from the Gamble house. I have an aluminum french cleat system marketed by (I think) FastCap. Hoping it works well!

Its 72" long and 32" tall from the top to the bottom of the center leg. Thhere will be an antique ceramic tile framed in the center. The rendering below is a meager attempt at some AI enhancement courtesy of SketchUp.

It will be walnut with ebony accents. The back plate takes its deign ques from several ceiling fixtures, primarily from the Gamble house. I have an aluminum french cleat system marketed by (I think) FastCap. Hoping it works well!

Its 72" long and 32" tall from the top to the bottom of the center leg. Thhere will be an antique ceramic tile framed in the center. The rendering below is a meager attempt at some AI enhancement courtesy of SketchUp.